Technology

Introduction: The Age of Intelligent Construction

The construction industry is undergoing a profound transformation. Artificial Intelligence (AI), once a distant promise, is now a central catalyst driving innovation, productivity, and competitive advantage. As costs rise, skilled labor declines, and timelines compress, AI offers powerful tools to rethink how projects are designed, delivered, and maintained. Yet, the true potential of AI emerges when it’s embedded into a fully integrated construction model:

One Company, One Solution.

This approach consolidates design, engineering, manufacturing, and field operations under one entity, ensuring that AI isn’t just an add-on-it becomes the operational core of a smarter, faster, and more predictable construction process.

The Benefits of AI in Construction

-

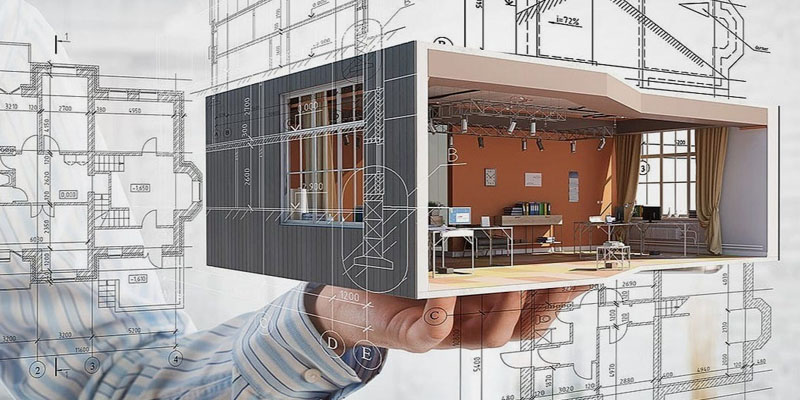

Data-Driven Design and Generative Planning

AI-powered generative design tools don’t just produce layouts-they evaluate hundreds of possibilities in seconds based on performance criteria such as cost efficiency, environmental impact, material usage, and space optimization. For modular construction, these tools can automatically align module sizes with standard material dimensions and factory capabilities, significantly reducing design-to-fabrication friction.

-

Enhanced Cost and Schedule Accuracy

AI platforms continuously learn from past project performance, regional labor trends, and supplier pricing data to provide real-time cost modeling. They detect scope gaps, estimate project timelines with greater precision, and can even model multiple delivery scenarios to advise which schedule path is most efficient-all before a bid is submitted.

-

Predictive Risk Management

By analyzing project data and market signals, AI systems can proactively identify high-risk subcontractors, safety hazards, or scope conflicts. These tools create risk heat maps and simulate outcomes based on weather, labor availability, or supply chain events, allowing construction managers to plan around disruptions before they happen.

-

Supply Chain Optimization

AI integrates directly with supply chain and ERP platforms to create dynamic procurement schedules. It flags upcoming shortages, recommends alternate vendors based on performance history, and automatically triggers orders aligned with production schedules. In modular construction, this ensures that critical components arrive just in time for assembly without warehouse bottlenecks.

-

On-Site Quality Control and Safety

Using computer vision and drones, AI systems inspect work in real-time, comparing installed components to digital twins or BIM models. They identify out-of-spec work instantly, track safety gear compliance, and send alerts for unauthorized site access or unsafe conditions. This enhances accountability and reduces costly rework.

-

Sustainability and Energy Modeling

AI platforms model environmental performance during design and monitor emissions and energy usage throughout the build. They recommend energy-efficient design alternatives and track a project’s alignment with LEED, WELL, and Net Zero goals. This is especially valuable in prefab where changes can be made early at the factory level.

The “One Company, One Solution” Advantage

The fragmented nature of traditional construction often causes data silos, miscommunication, and costly delays. A “One Company, One Solution” approach-where design, manufacturing, logistics, and construction teams are united under one organizational roof—creates the perfect environment for AI to thrive.

Why it works:

Unified Data Flow: All departments share a centralized data environment, allowing AI tools to seamlessly use project data across design, procurement, scheduling, and field execution. This enables continuous optimization and feedback loops.

Faster Decision-Making: With no external stakeholders slowing the flow of information, AI-generated insights (e.g., scheduling conflicts, cost overruns, material delays) can trigger immediate internal responses-accelerating resolution and improving agility.

Accountability and Consistency: One organizational structure means one set of KPIs, one culture of quality, and one source of accountability. AI can track project health, vendor performance, and compliance uniformly across all stages without cross-company variance.

Optimized Modularity: AI can coordinate between the design team and factory floor to ensure that modular units are not only structurally sound but also optimized for transportation, installation sequencing, and future maintenance-resulting in flawless field fit and faster commissioning.

Looking Ahead

The future of construction won’t be led by the biggest firms-but by the smartest. AI is not just a digital overlay, but a foundation for rethinking the very structure of how we build. When coupled with an integrated, vertically aligned model like “One Company, One Solution,” AI becomes more than a tool; it becomes a competitive advantage.

Construction firms that embrace this model will achieve faster schedules, reduced costs, fewer errors, and more scalable growth. The convergence of AI and integration isn’t coming. It’s already here.